- Email: [email protected]

- Call: +441326 369469

© Mintmech Ltd

Specialist equipment comes in all shapes and sizes, from downhole tooling and safety systems to robust deck handling and automation equipment. We develop unique solutions engineered for the harshest of environments.

Drawing on decades of machine design and a deep understanding of complex offshore operations, we work hard to fully understand the challenges our clients face and work collaboratively to engineer custom solutions.

From concept consultancy to fully commissioned, we oversee and facilitate a wide range of projects internationally.

Design

We take high-level concepts through to class-approved detail design - employing highly effective problem-solving, next generation engineering software and classic hand calculation, and a no-nonsense design for manufacture ethos.

Build

Our experienced team of engineers manage the manufacture and acceptance testing process of all projects. We work in partnership with a reliable network of long-term suppliers to ensure the highest quality standards.

Commission

We undertake site commissioning and installation. Completed efficiently and safely, our well-planned mobilisations allow thorough equipment testing and sign-off to be combined with structured operator training.

The MMIRN MK2 iron roughneck is designed to connect and disconnect segments of pipe on geotechnical offshore drilling rigs. This specialist machine negates the need for manual operation and critically improves safety and productivity. It is engineered in accordance with DNV with a bespoke steel design and custom control system.

MintMech’s CTV jack up ladders (JackLad) permit safe access and egress from <6.5t CTVs to offshore structures. They feature a unique shock absorption system and are designed to encompass a 9m range with 12 operational positions. Identified by the International Jack Up Barge Operators Association (IJUBOA) as ‘best practise access solution’.

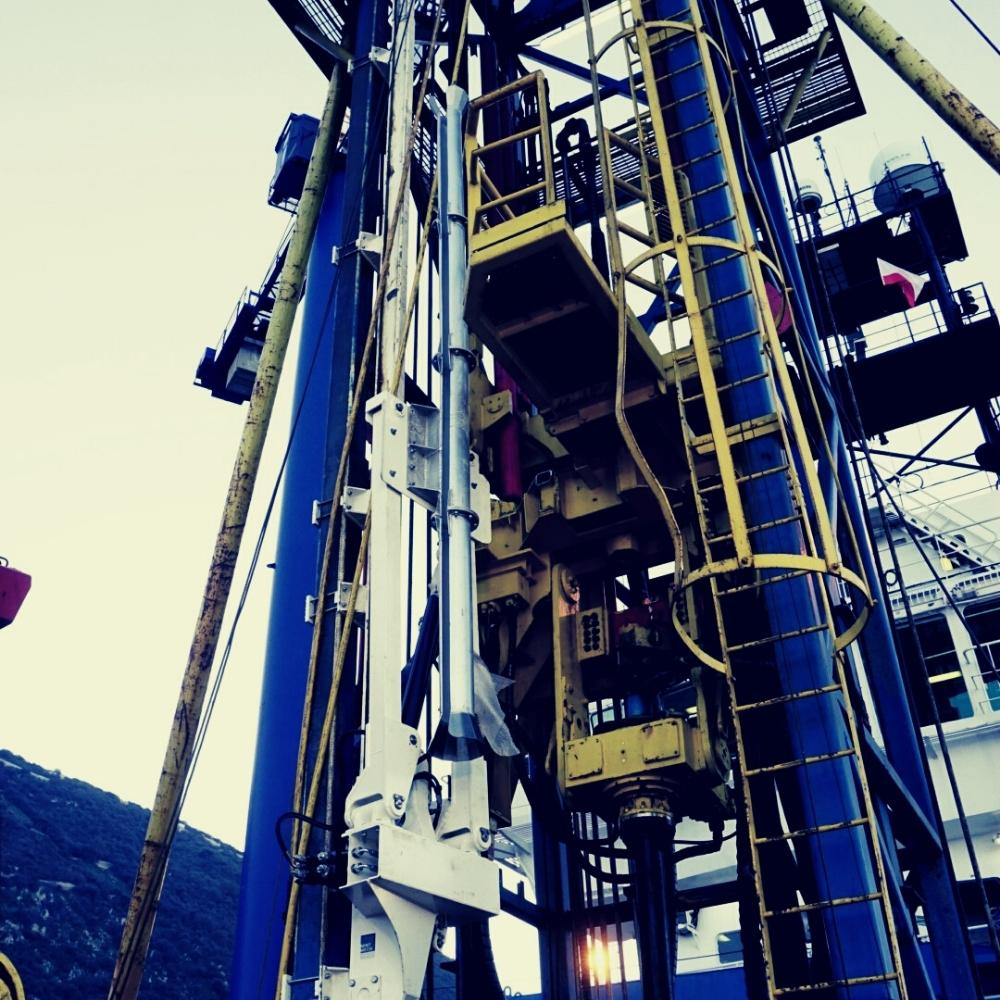

The MM RTH MK3 handles downhole tooling with minimal operator intervention or manual handling and removes roosterbox / compensated platform access and handover requirements during drilling, greatly improving personnel and operational safety. The semi-automated electro-hydraulic system features wireless remote control, manual backup control and electrical positioning monitoring that combines with drill position to provide full interlocking. As is standard in MintMech equipment, the system is designed with operation and maintenance personnel in mind, with zero fabrication installation allowing installation onto the drill derrick within 2 days.

MintMech’s retrofittable Active-Heave-Assist Compensation System was created to improve the geotechnical drilling performance of existing assets. By piggybacking on the existing passive heave compensation system, the AHA system allows the driller to easily command the drill string to remain stationary relative to the seabed as a vessel heaves up and down, regardless of system friction. This allows displacement controlled drilling methodologies to be used to core and geotechnical sample soft and fractured geologies with ease.