- Email: [email protected]

- Call: +441326 369469

© Mintmech Ltd

In marine construction, a wide range of different foundations and anchoring or mooring systems exists. Whether a monopile for an offshore wind turbine or an anchor for a floating substation, the optimal solution depends on the ground conditions.

After a desk study of the proposed project area, contractors collect more detailed information with a site investigation. A site investigation typically includes a geophysical survey and a geotechnical survey.

First, the geophysical survey offers broad, indirect insights that guide where and how to conduct geotechnical investigations. Then, the geotechnical survey delivers the precise, hands-on data needed for final engineering decisions.

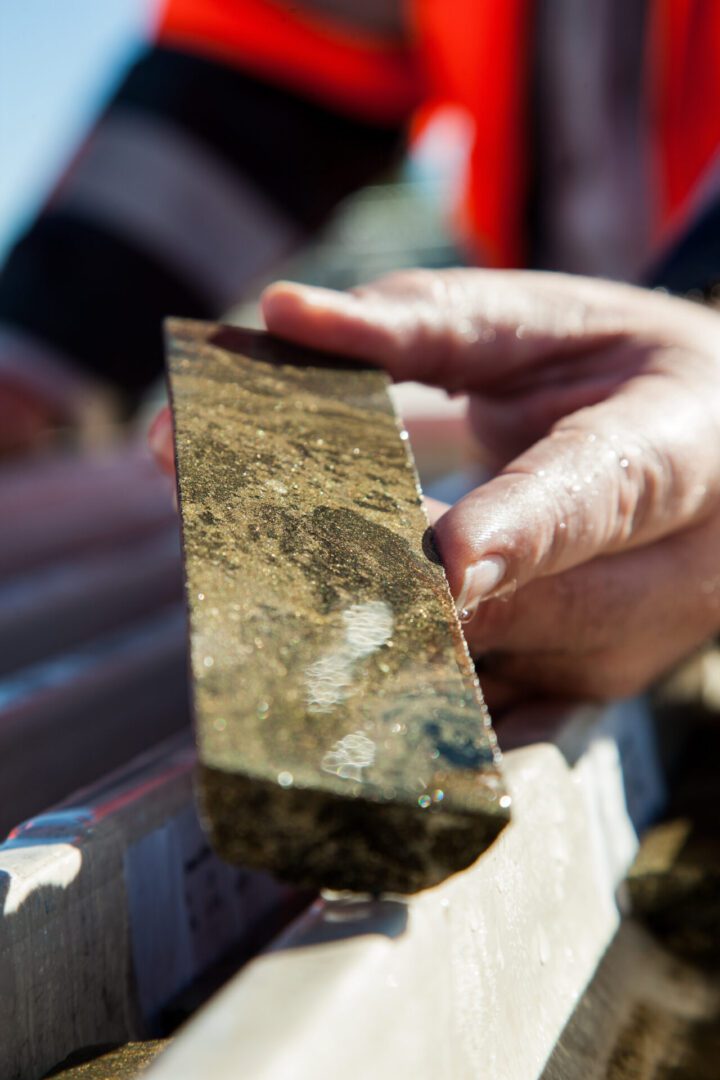

The geotechnical survey involves using specialised machinery and different types of drills and drilling techniques to collect samples of soil and rock from the seabed. These cores give engineers a detailed understanding of the sediment’s characteristics, such as its composition, strength and stability.

In essence, geotechnical drilling and sampling provides the critical data needed to build safely, efficiently and sustainably.

The information from core samples helps determine the most viable and cost-effective foundation design for the project. For example, different sediment types such as clay, mudstone or chalk have distinct load-bearing properties. The more designers know about the seabed, the better they can strike the balance between durability and installation costs.

Accurate site investigation is crucial to avoid overlooking potential issues in the seabed’s composition because undetected problems can significantly escalate project costs. In extreme cases, when a project is already well underway, the ramifications of unexpected issues can be two or three times the planned total project cost.

Cores collected during geotechnical drilling operations represent a considerable investment of time and money. Unplanned downtime often increases the costs of obtaining these cores because marine geotechnical surveys face several key challenges, including:

By recognising these challenges and employing the right equipment and engineering solutions, marine geotechnical teams can ensure quality data collection and successful marine construction projects. Partnering with a marine engineering specialist can help. At MintMech, we recognise the need for precision, reliability and a deep understanding of the challenges of working offshore.

Our team of experienced engineers has a proven track record of delivering tailored support for a wide range of offshore projects. For information on how we can customise support to align with your project’s requirements, schedule and regulatory landscape, get in touch for a free consultation.

Client representation

Maintenance management

Equipment upgrades

Mobilisation support

We continue to provide operational and technical expertise supporting JOGMEC’s pioneering ultra-deep geotechnical exploration project in Japan. This project provides some of the most challenging geotechnical conditions, combining deep water drilling, complex seabed formations and hydrothermal vents to navigate.